Sterile Motors, Piezo Transducers: Precision Motion for Medical Design |

|

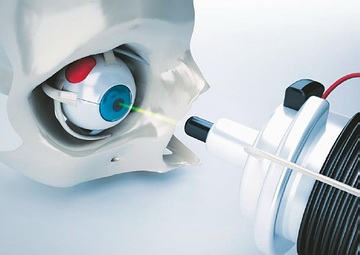

Piezo Laser Steering Mirror Mounts and Focusing Systems for Ophthalmology / Refractive Surgery | ||

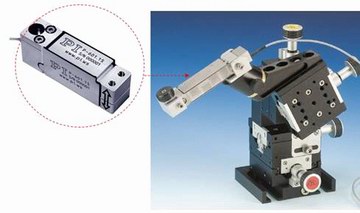

Piezo steering and fast focusing devices are used in Ophthalmology.

| PI's compact piezo steering mirror mounts provide many advantages over classical beam deflection methods. Laser beam control and focusing requires high-precision positioning systems. Piezoceramic based solutions work with extreme precision and speed. They boast extreme reliability (PI piezo actuators are employed on the Mars mission), and compact size for easy integration in today's laser systems. Read: Advances in Piezo Mechanics and Eye Surgery | |

Piezo Motion & Engineered Nanopositioning Systems: Key to Nanometer Sized Features | ||||

| Watch Video Webinar: Piezoelectric Transducers for Liquid Handling, IVD, PoC, Cytometry, Array Spotting | ||||

Miniature 6-Degree of Freedom Hexapod Robotics PositionerPrecision Handling, Testing, Assembly |

Read more about Hexapod Medical Robots (6-Axis Hexapods) |

Miniature hexapod positioners are perfectly suited for precision assembly and alignment applications of small, high precision parts. They provide extremely flexible motion in all degrees of freedom, plus a programmable center of rotation. PI hexapods come with an easy to use controller and software that provides them with motion flexibility similar to the human hand.

PI's H-810 and H-811 miniature 6-Axis positioners combines all advantages of PI’s high load tried and proven parallel-kinematic robot systems in the smallest of packages. With a diameter of only 10 cm and a height of less than 12 cm, the M-810 offers travel ranges of up to 40 mm in the XY plane and 13 mm in the Z direction. Despite of its small size, the hexapod can reliably position loads of up to 5 kg at velocities of 10 mm/s. The small envelope was made possible by the usage of new technologies for encoders, motors and reference switches. Nevertheless, the Mini-Hexapod is 100% compatible with PI's tried and proven hexapod controllers and software. As with other parallel-kinematics positioners from PI, the six high resolution actuators are connected directly to a single moving platform. The user is able to define the center of rotation (pivot point) independent of platform motion with a simple software command. In contrast to conventional, stacked, multi-axis systems, there is no accumulation of guiding and lever-arm induced errors Technical Specifications

Read Hexapods Enable Precise 6-Axis Patient Positioning Couches for Radiotherapy

|

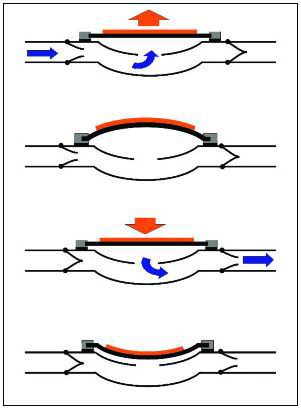

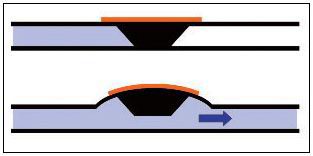

Piezoelectric Transducers and Assemblies for Micro Pumps and ValvesPrecison Dosing of Microliter Volumes | ||

Piezo = Miniaturized Technology Displacement pumps are used worldwide in many diverse branches of industry. Increasing miniaturization means the market for their smaller “relatives“ is also growing: Microdispensers take on distribution and dosing tasks where small volumes in the milliliter, microliter or nanoliter range have to be controlled. Piezo is the Driving Force The design is based on the familiar principles of diaphragm pumps and valves and also makes use of the peristaltic principle. The miniaturized drives are based on piezoelectric actuators in various shapes and degrees of integration.

|

Wide Range of Applications for Flexible Technology In drug discovery and medical engineering, biotechnology or chemical analysis, tiny dispensers accurately dose active substances or medicines. Micropumps take care of the removal of reaction gases in closed processes. Read Article: Motion Control, Piezo Transducers, Motors for Medical Design

| |

|

Micro-Diaphragm Pumps

|

Adapted for Precision & Force The properties of the pump media – viscosity and drop size, for example – determine the different forces which have to be applied and hence the size and type of the piezo actuator used. The piezo displacement is a variable parameter which controls the dosing volume. With micropumps, the frequency also determines the flow rate that can be achieved.

Feature Article in European Medical Device Technology Magazine:

Precise Liquid Handling for in Vitro Diagnostics

| |

PiezoMove: Moving, Positioning, Scanning |

Piezo linear actuators can be used in micro-valves, particularly where viscous liquids with a tendency towards higher back pressures are processed; where larger strokes of the valve tappet are required, with lever amplification as well.

|

Piezo = nano precision = exotic? Piezoelectric actuators provide a lot more benefits than “just“ precision. Their excellent dynamics and high force also play a crucial role in many areas, where nanometer precision is not (yet) required: e.g. for fast switching, vibration cancellation, or to adjust tools in machines. In these applications the piezo actuator is one – if not the only – solution and in the case of the new Piezo Move OEM actuators, at a very attractive price. PI supplies a variety of standard integration levels and also customized versions: From simple piezo stack components and preloaded linear actuators through to 6-axis positioning systems with subnanometer precision. Feature Article in EMDT Magazine:

Piezo Motors and Actuators: Streamlining Medical Device Performance

|

Electrophysiology: Piezos Enable Faster Solution Switching | ||

Siskiyou’s MXPZT-300A fast solution Switcher is based on a fast piezo flexure actuator

| Electrophysiological studies require fast motions of a double- bore (theta-glass) pipette across cell membranes. With a cell held in a patch clamp and monitored electrically, one bore of the pipette flows a buffer solution, while the other carries a drug or other chemical. By quickly sweeping the pipette so one bore or the other suffuses the cell, its electrophysiological response can be correlated to the chemical environment. Piezos are ideal for fast switching, as they offer electromagnetic quietness, good repeatability, high reliability and fast speeds. However, fast acceleration can mean recoil forces excite vibration in the pipette and both piezo and stepper actuators have suffered from these in the past. These cause unwanted, repetitive solution switching for many milliseconds. Paper: Electrophysiology - Transducers Enable Faster Solution Switching | |

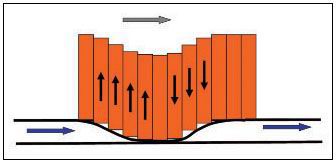

Ultrasonic Piezos Drive Medical Engineering |

The continuing miniaturization in medical engineering places ever increasing demands on the components. Piezo drives are the solution for many motion control applications; the piezo effect efficiently generates fast and precise motion while requiring very little space.

Efficient Aerosol Generation with Piezoelectric Ultrasonic Transducers

|

Moreover, the piezoelectric transducer technology reduces the time required to atomize medications by up to 50 % compared to conventional systems increasing the quality of life for patients with chronic diseases.

Piezo ceramics meet the special hygiene requirements in medical engineering; the aerosol generators can be sterilized at high temperatures, even in autoclaves. The ultrasonic operation is soundless for humans, and the low power consumption of the piezo components allows battery operation.

Piezoelectric Drives in Microfluidics Lab-on-a-chip applications are made possible by the minute dimensions. |

Different Types of Piezo Actuators Solve Different Problems |

Direct Actuators: Piezo Stacks, Shear (X, XY)

| Ampliied Piezo Flexure Actuators

| |

Ultrasonic Linear Motors

|

PiezoWalk® Linear Motors

| |

All: Sterile, Low Power, No Lubricants, Non- Magnetic, Vacuum Compatible; High Resolution:

| ||

Non-Magnetic Motors |

|  |

| ||

Ultrasonic Motor

|

OEM PiezoWalk® Linear Motor

|

PiezoWalk® Linear Actuator

|

Dispensers for Bio-Handling | ||

Low profile linear actuators, shown with well plate. The integrated ceramic piezomotor provides high speeds. Piezo ultrasonic motors are compact, provide high speed and have other advantages compared to conventional motors and screw driven motorized actuators |

– particularly when the stages must be small and fast. They achieve positioning accuracies of up to 0.1 µm and speeds of up to several 100 mm/s.

Small and fast is not only a requirement in classical micropositioning technology, however. Piezo ultrasonic motors are also extremely well suited to applications where the accuracy requirements are not quite so demanding – in the range between 5 and 100 micrometers for example, which is usually sufficient for industrial automation and handling tasks. PI provides a number of compact actuators that can be used in precision dispensing application. |

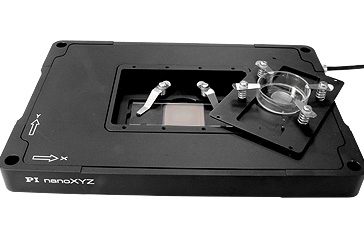

Piezo Stages for Bio-Medical Imaging and Microscopy |

|  |

| Articles and Papers: Piezo & Precision Actuator Systems in Bio-Medical Applications: |

Faster than the Speed of Hearing: Nanomechanical Force Probes Enable the Electromechanical Observation of Cochlear Hair Cells

Inner Ear Research: Piezo chip actuator in research for Stimulation of hair cells in the inner ear

Faster than the Speed of Hearing: Nanomechanical Force Probes Enable the Electromechanical Observation of Cochlear Hair Cells

Inner Ear Research: Piezo chip actuator in research for Stimulation of hair cells in the inner ear |

Biomedial Imaging:

Biomedial Imaging: Characterizing point spread functions of two-photon fluorescence microscopy in turbid medium |

Electrophysiology: Piezo Technology Enables Faster Solution Switching

Electrophysiology: Piezo Technology Enables Faster Solution Switching |

Piezoelectric Effect and Growth Control in Bone

Piezoelectric Effect and Growth Control in Bone |

P-239 Piezo Actuator Medical Application: Development of a Mechanical Testing

P-239 Piezo Actuator Medical Application: Development of a Mechanical Testing and Loading System for Trabecular Bone Studies |

M-126 Precision Linear Stage and M-231 Linear Actuator Application in Medical Robotics and

M-126 Precision Linear Stage and M-231 Linear Actuator Application in Medical Robotics and Computer Assisted Surgery MEM Surgery: an integrated test-bed for vascular surgery |

Hexapod Bio-Medical Application: A technical review on the

Hexapod Bio-Medical Application: A technical review on the orthopedic compliant robotic arms |

PI Hexapod Application in Medical Engineering Adaptation of a hexapod-based robotic system for extended

PI Hexapod Application in Medical Engineering Adaptation of a hexapod-based robotic system for extended endoscope-assisted transsphenoidal skull base surgery |

M-850 Hexapod Neuro Surgery Application: A robotic neuro-surgery system and its

M-850 Hexapod Neuro Surgery Application: A robotic neuro-surgery system and its calibration by using a motion tracking system |

M-230 Precision Actuator Application in Medical Engineering Time kinetics of bone defect

M-230 Precision Actuator Application in Medical Engineering Time kinetics of bone defecthealing in response to BMP-2 and GDF-5 characterised by in vivo biomechanics |

M-850 Hexapod Bio-Medical Application: A Stewart platform for precision surgery

M-850 Hexapod Bio-Medical Application: A Stewart platform for precision surgery |

M-850 Hexapod Dental Test System Engineering Application

M-850 Hexapod Dental Test System Engineering Application |

M-850 Hexapod Application in Medical Engineering: Eine konfokale Messsonde zur hochpräzisen

M-850 Hexapod Application in Medical Engineering: Eine konfokale Messsonde zur hochpräzisen navigierten Felsenbeinchirurgie |

Custom M-850 Hexapod as Medical Robot for Spine Surgery

Custom M-850 Hexapod as Medical Robot for Spine Surgery |

M-840 Hexapod Bio-Medical Application: Subcellular Motion Compensation for

M-840 Hexapod Bio-Medical Application: Subcellular Motion Compensation for Minimally Invasive Microscopy, In Vivo. Evidence for Oxygen Gradients in Resting Muscle |

Custom M-850 Hexapod as Medical Robot for Spine Surgery

Custom M-850 Hexapod as Medical Robot for Spine Surgery |

M-824 High Precision Hexapod Bio-Medical Application in Prospective head movement correction for high

M-824 High Precision Hexapod Bio-Medical Application in Prospective head movement correction for high resolution MRI using an inbore optical tracking system |